Description

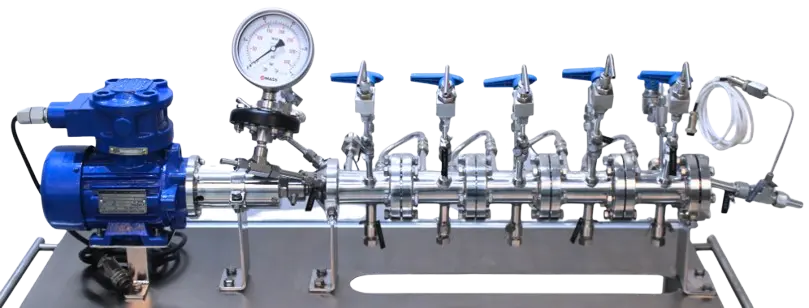

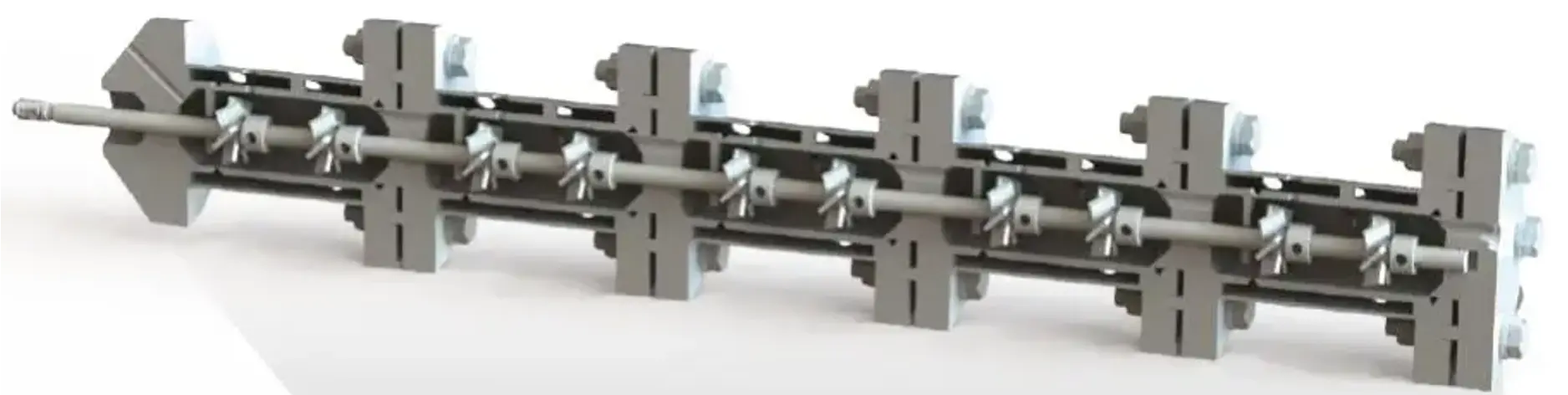

The Halen SFR 100 dynamic flow reactor, distributed from our partner, is a versatile continuous reactor engineered for demanding slurry reactions. Its modular cell design allows multiple cells to be equipped and magnetically coupled with impellers for active agitation, ensuring uniform dispersion of the reaction media. The intense mixing maximizes heat transfer to the jacketed reactor walls, maintaining isothermal conditions for the multiphase flow process. Capable of handling most demanding slurry feeds and/or precipitation reactions at high pressures and temperatures, the Halen SFR 100 reactor is the ideal vessel for effective process intensification from the process development phase up to commerical scale. Available as flameproof skid modules from production.

Technical Specifications

Halen SFR 100

|

Design pressure |

20 up to 50 barg |

|

Temperature range |

-30 to 250 °C |

|

Reactor volume |

250 mL up to 50 L |

|

Production capacity |

1 - 1000 MT/year |

|

Residence time range |

1 min - 30 min |

|

Material of construction |

SS 316L, Hastelloy C, Glass with Metal |

Hydrodynamic profile | Tanks in series (10 CSTR's for 5 cell setup) |

Mode of operation | Continuous |

Heterogen. reactions | Yes |

Heat exchanger | Cooling/heating jacket |

Ex-proof | Available as flameproof skid module ATEX or NEC 500 (Class 1 / Div 2) |

Regulatory compliance | GMP, FDA, REACH, RoHS, USP, PED |

Control & automation | Local & DCS operation |

Applications

- Heterogeneous catalyzed reactions

- Precipitation reactions

- Nucleophilic substitutions

- Aldol condensations

- Esterifications

Contact us for your chemistry!