Description

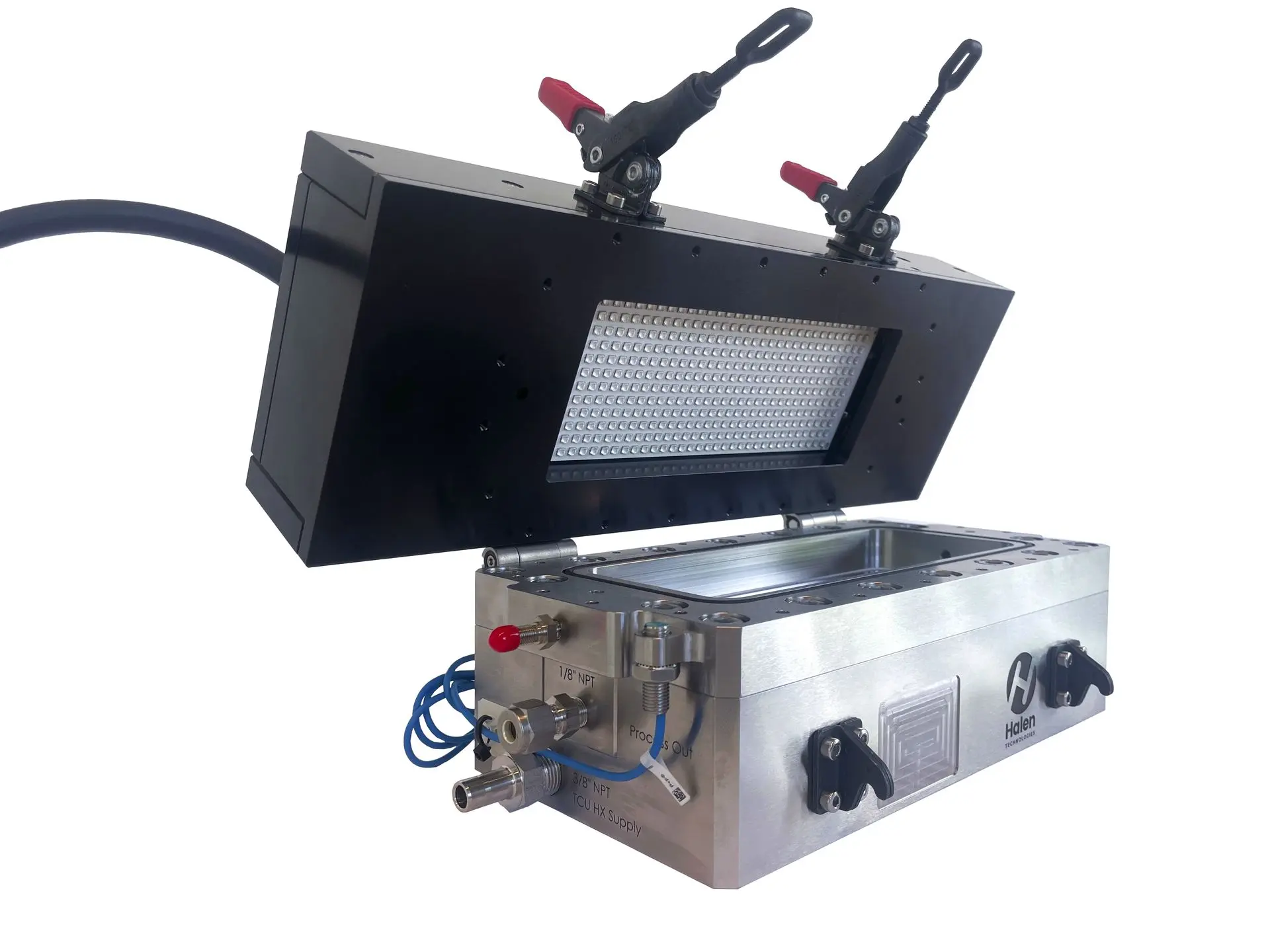

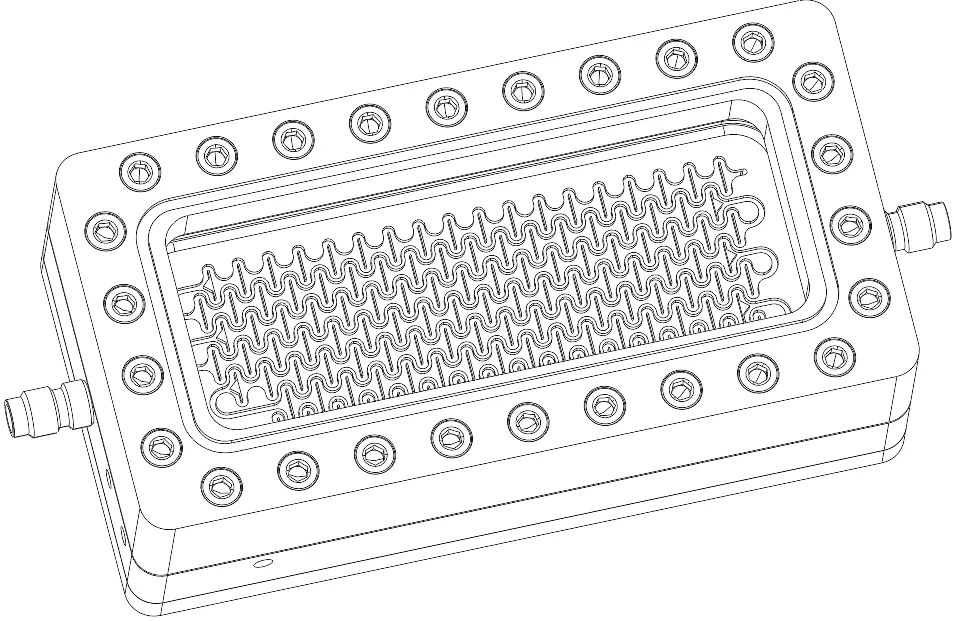

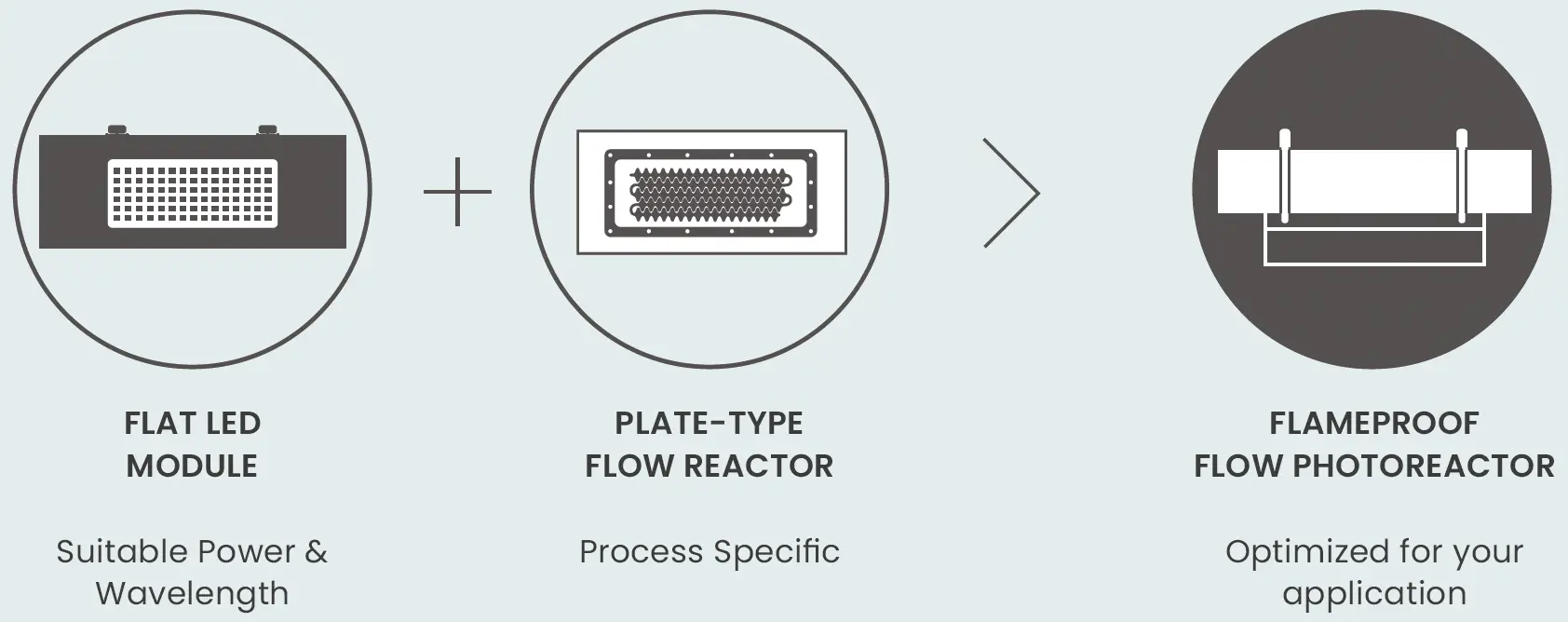

The Halen XFR 200 reactor series combines split-and-recombine serpentine plate flow reactors with the proprietary high-power flat LED technology developed by Peschl Ultraviolet GmbH. Our plate-type flow photoreactors provide excellent mixing characteristics, regardless of the residence time, and their flameproof design meets the requirements for commercial production.

The photonic energy generated by the LEDs in combination with the small volume of the flow reactor requires detailed modeling to secure the safe operation. We cooperate with a specialized party for CFD (Computational Fluid Dynamics) simulations on all our plate-type flow reactors.

Our reactors are engineered specifically for your process needs and provide a wide range of reactor volumes, high-pressure rating and minimal pressure drop. For production, multiple photoreactors can be cascaded into turnkey flameproof plants.

The plate flow photoreactors can be operated in different flow modes with excellent mixing providing a solution for precipitation or slurry phase photoreactions, even with prolonged irradiation times. The reactor‘s easy disassembly allows for straightforward inspection and cleaning validation, meeting GMP guidelines.

Key Features

Heterogeneous Photocatalysis & Precipitations

Long Residence Time Reactions

CFD-Driven & Flameproof Reactor Design

Excellent Cleanability & Low Dead Volume

Multi Ton/year Production Capacity

Technical Specifications

Halen XFR 200

|

Design pressure |

16 barg |

|

Temp. range |

-20 to +100 °C |

|

Reactor volume |

1 - 20 mL per reactor cell |

|

Production capacity |

0.1 - 10 MT/year (6 cells unit) |

|

Residence time range |

<10 sec - 30 min |

|

Material of construction |

SS 316 or Hastelloy C |

Hydrodynamic profile | Plug flow |

Mode of operation | Continuous |

Heterogen. reactions | Yes |

Heat exchanger | Build-in heat transfer fluid system |

Amount of lamps | 1 lamp per reactor cell |

LED power consumption | Up to 1600 W per lamp |

Available wavelength | 365/385/395/405/420/460/525/592/625 nm |

Optical path | 0.2 - 2 mm |

Ex-proof | ATEX & NEC 500 (Class 1 / Div 2) |

Temperature class | T4 (Tmax 135°C) |

Regulatory compliance | GMP, FDA, REACH, RoHS, USP, PED |

Control & automation | Local & DCS operation |

Applications

- API & intermediate synthesis

- (Metalla)photoredox cross-couplings (e.g., Cross-electrophile Csp2-Csp3 coupling)

- Mercaptan synthesis (e.g., Cyclohexylthiol via H2S addition)

- C-H Functionalizations (e.g., C-H alkylation of heteroarenes)

- Fluoroalkylations (e.g., Late-stage trifluoromethylations)

Contact us for your chemistry!