Description

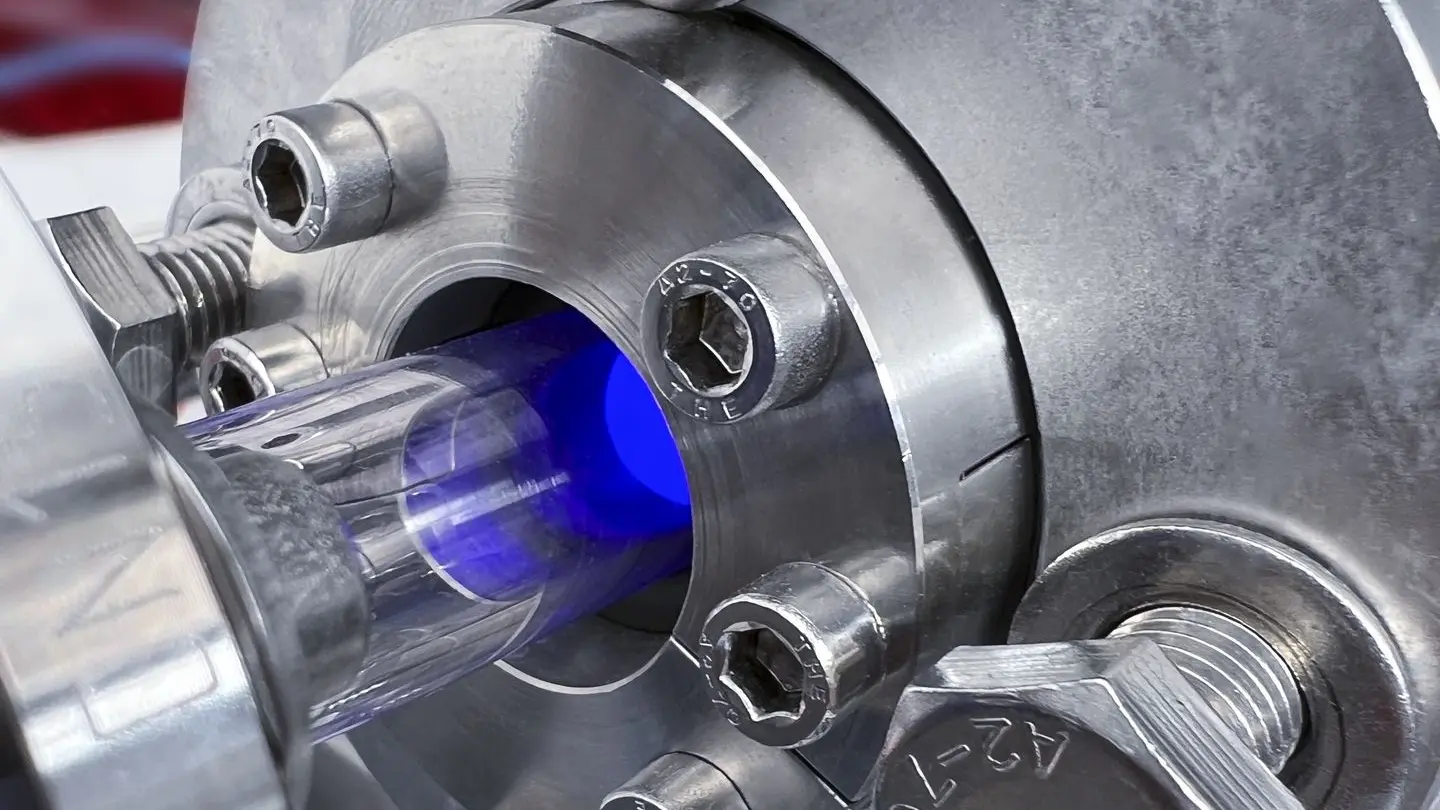

In collaboration with Peschl Ultraviolet GmbH, the tubular flow photoreactors use exchangeable FEP or glass tubes, mounted via a modular carrier design. These carriers are submerged in a temperature-controlled bath to safeguard excellent temperature regulation of the continuous-flow process.

At the center of the carrier is a high-performance LED or a medium-pressure light source, with an independent, proprietary thermofluidic system for thermal decoupling of the lamp and flow reactor.

The concentric profile ensures that the photons are effectively utilized in the process without significant reflection loss for both UV and visible light photochemistry applications.

The precise control of photochemical reactions in continuous flow improves the reliability throughout the reaction, combined with minimal hold up volume, making it making it the safest and best available solution for pharmaceutical and fine chemical applications. The excellent process control limits the formation of by-products otherwise caused by over-irradiation.

Our photoFLOW reactors can be operated in different flow modes and scaled down to lower volumes for early development. The combination of the excellent temperature and process control makes photoFLOW the ideal solution for commercial-scale production.

Key Features

Multipurpose Liquid Phase Photochemistry

Mainly UV & Visible Ligh Direct Activations

Complete Thermal Decoupling of Lamps (Proprietary)

Exchangeable Tube Carriers (Variable Optical Path)

Production Capacity for APIs & Fine Chemicals

Technical Specifications

photoFLOW

|

Design pressure |

4 bar (Glass) / 20 bar (FEP) |

|

Temperature range |

-10 up to +100 °C |

|

Reactor volume |

1 - 3.7 L |

|

Production capacity |

1 - 100 MT/year |

|

Residence time range |

20 sec - 15 min |

|

Tube carriers |

Glass or FEP |

Hydrodynamic profile | Plug flow |

Mode of operation | Continuous |

Heterogen. reactions | No |

Heat exchanger | Cooling/heating jacked |

Amount of lamps | 1 |

LED power consumption | 1000 up to 5000 W |

Available wavelength | High-power LED or |

Optical path | 5 - 25 mm |

Ex-proof | ATEX & NEC 500 (Class 1 / Div 2) |

Temperature class | T4 (Tmax 135°C) |

Regulatory compliance | GMP, FDA, REACH, RoHS, USP, PED |

Control & automation | Local & DCS operation |

Applications

- Brominations for API intermediate synthesis

- Rearangements (e.g., Norrish)

- Isomerizations (e.g., Iribotecan by cis-trans isomerization)

- Singlet-oxygen reactions (e.g., Artemisinin and rose oxide synthesis)

- Cycloadditions (e.g., oxetane intermediates via Paternò-Büchi reaction)

Contact us for your chemistry!