Description

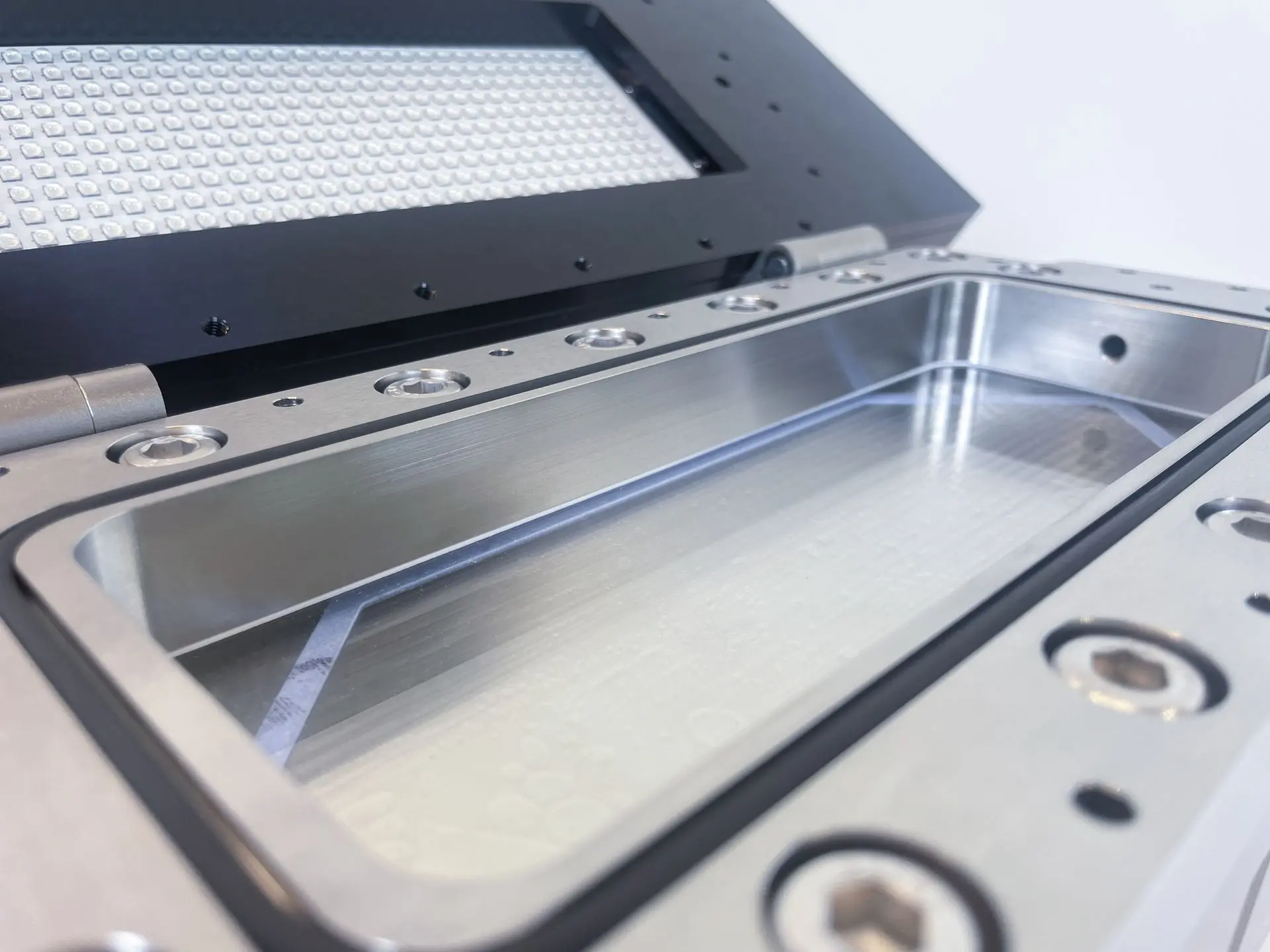

The HALEN TFR 200 is specifically developed for photoreactions involving species with high absorption coefficients. These processes exhibit low transmittance, as photons are absorbed almost instantly at the exposed surface.

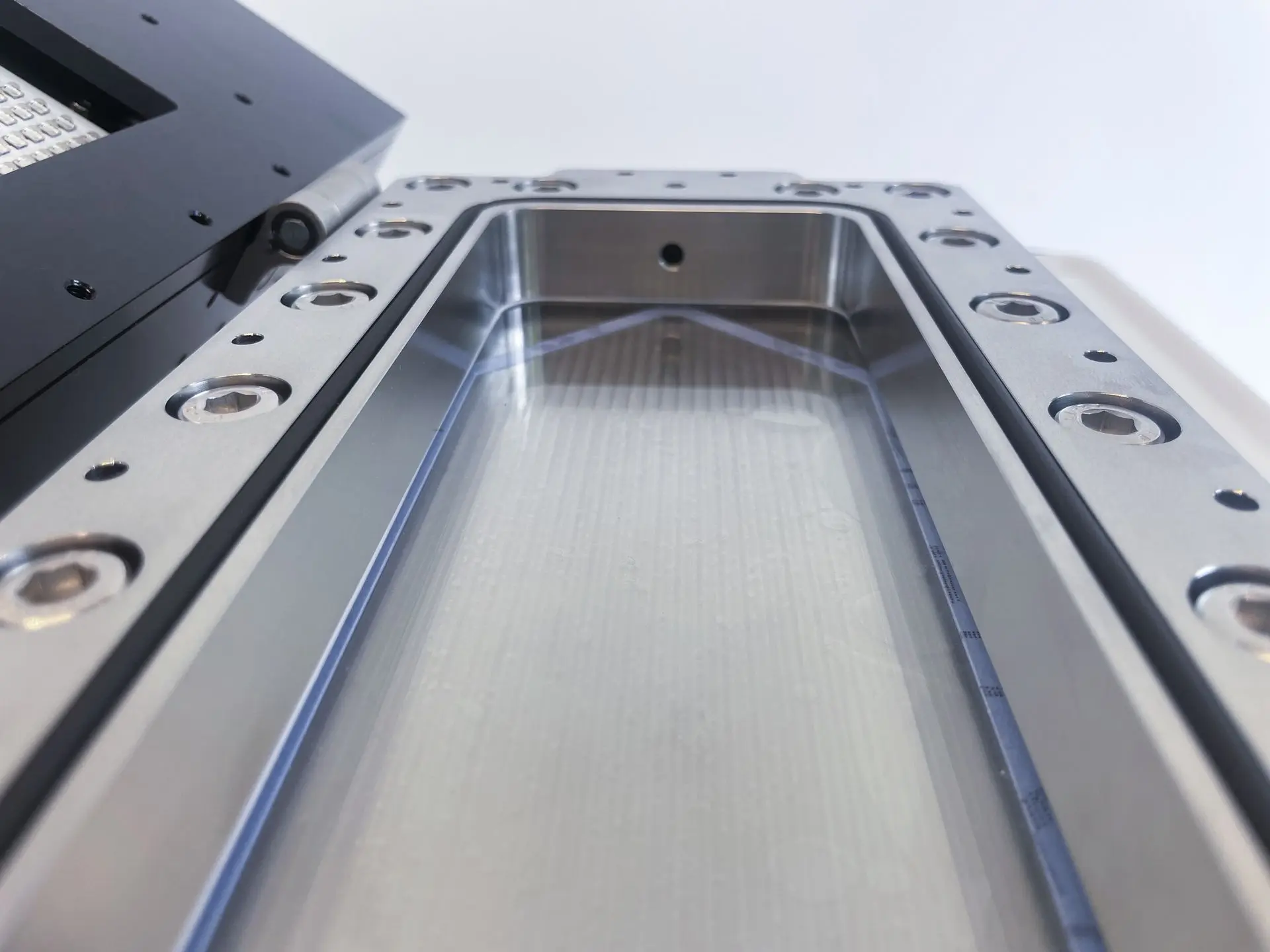

With our HALEN TFR 200, we offer high-absorption photochemistry at commercial scale. The reactors are designed to optimize the irradiation of the process stream by generating a thin film that is precisely tailored to the absorption profile. This safeguards efficient irradiation of the entire process liquid as it flows through the film, maximizing photon utilization and reaction efficiency.

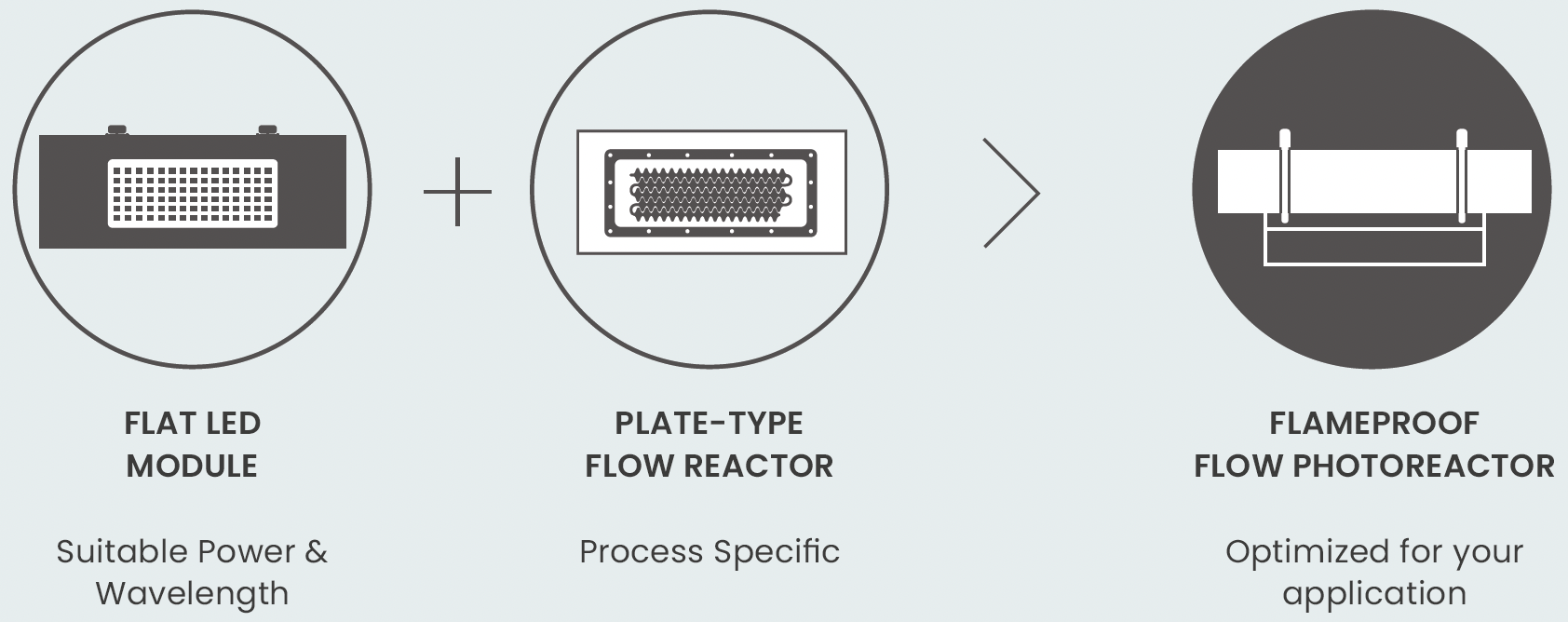

Equipped with the proprietary high-power flat LED technology developed by Peschl Ultraviolet GmbH, these flameproof flow photoreactors are designed for commercial production. The photonic energy generated by the LEDs in combination with the small volume of the flow reactor requires detailed modeling to secure the safe operation. We cooperate with a specialized party for CFD (Computational Fluid Dynamics) simulations on all our plate-type flow reactors.

Our reactors are engineered with high-pressure rating and minimal pressure drop. For production, multiple photoreactors can be cascaded into turnkey flameproof plants.

With the HALEN TFR 200 reactors, photochemical reactions involving highly absorbing substrates can be successfully scaled to commercial production.

Key Features

Designed for High Absorbing Processes

Adaptive Thin Film Layer for Optimal Irradiation

CFD-Driven & Flameproof Reactor Design

Excellent Cleanability & Low Dead Volume

Suitable for Commerical-scale Production

Technical Specifications

Halen TFR 200

|

Design pressure |

Up to 16 barg |

|

Temperature range |

-20 up to +100°C |

|

Reactor volume |

1 - 10 ml per reactor cell |

|

Production capacity |

Up to MT/year |

|

Residence time range |

<10 sec - 30 min |

|

Material of construction |

SS 316 or Hastelloy C |

Hydrodynamic profile | Thin film laminar flow |

Mode of operation | Continuous |

Heterogen. reactions | No |

Heat exchanger | Build-in heat transfer fluid system |

Amount of lamps | 1 lamp per reactor cell |

LED power consumption | Up to 1600 W per lamp |

Available wavelength | 365/385/395/405/420/460/525/592/625 nm |

Optical path | <1 mm |

Ex-proof | ATEX & NEC 500 (Class 1 / Div 2) |

Temperature class | T4 (Tmax 135°C) |

Regulatory compliance | GMP, FDA, REACH, RoHS, USP, PED |

Control & automation | Local & DCS operation |

Applications

- API & intermediate synthesis with high absoprtion coefficient

- Photooxidations implying radical intermediates (e.g. AOP)

- Steroid-hormone synthesis (e.g., production of Vitamin D derivatives)

- Production of vitamins (e.g., Vitamin A)

- Fluoroalkylations (e.g., Trifluoromethylation with the Langlois reagent)

Contact us for your chemistry!